There are more solar panels on Australian rooftops than ever before, with solar power now representing the largest fuel source for electricity in Australia. And the latest data from the Australian Energy Council shows installations are still on the rise.

In the second quarter of 2023 alone, more than 61,000 new installations were added to the grid, bringing Australia’s total rooftop solar capacity to 20.5 GW, with that number projected to continue climbing.

With so much demand for solar, it’s no surprise that safety and compliance issues are becoming more frequent across the board. These issues can be frustrating, costly and in some cases, even dangerous.

That’s why our solar experts are sharing some common safety and compliance issues to look out for, and easy ways you can ensure the quality and compliance of your new solar system.

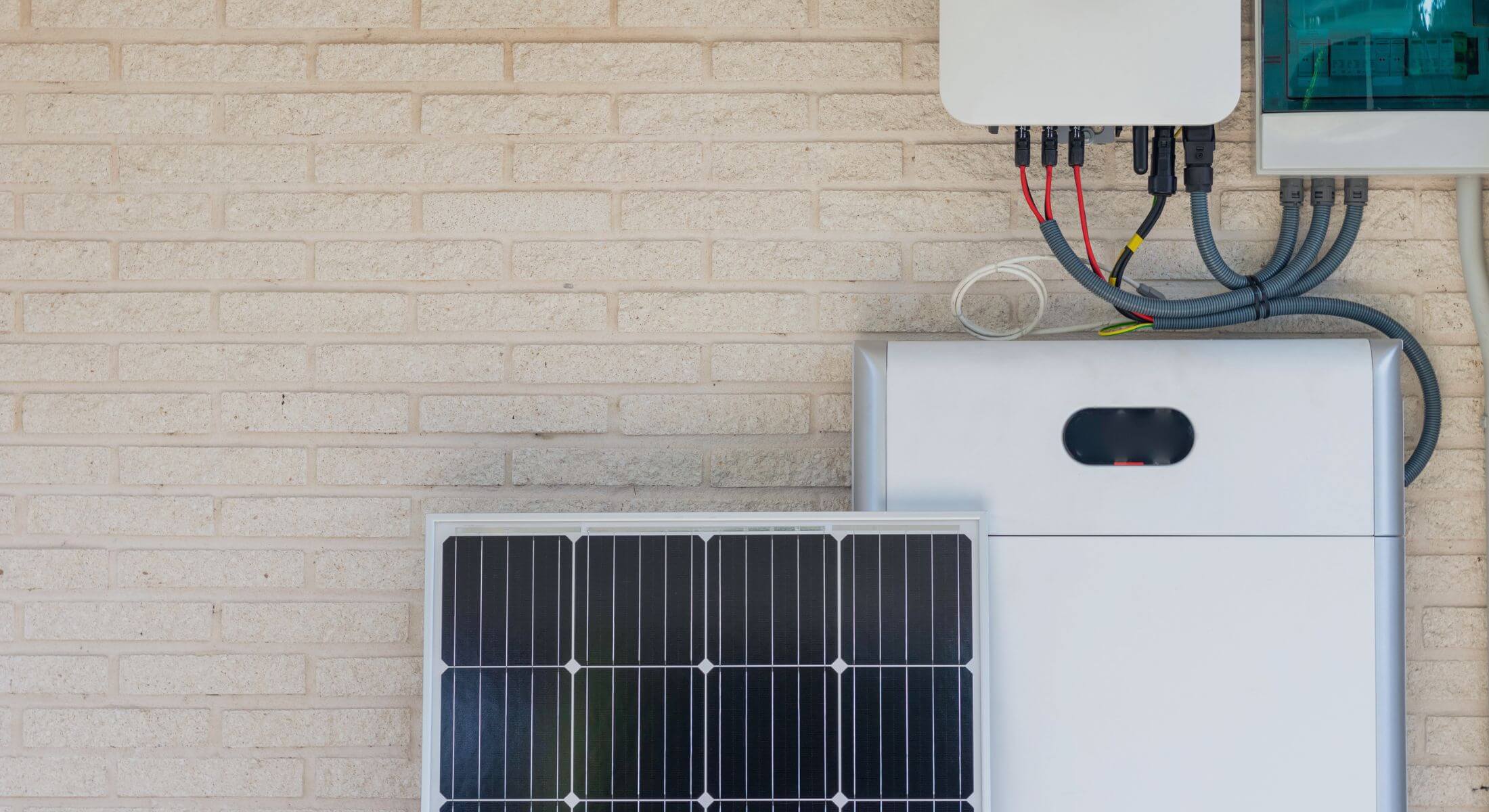

All solar systems are not created equal: avoiding poor quality components

While it’s not always true that more expensive = better quality, cheaper components will often be of a lower quality, from materials to construction. When choosing your panels, keep this in mind.

Poor quality components can affect performance and efficiency, lead to increased maintenance costs – and even contribute to a reduction in the lifespan of your solar system.

If you’re unsure about components, a reliable indicator of quality is ensuring that they meet Australian standards for use in the design and installation of solar PV systems.

Get advice from a solar expert now

Common installation issues for solar PV systems

Choosing the right installer for your system is key. Always ensure your installer – specifically the electrician providing the work – has an A- grade electrician ticket and is CEC accredited.

While CEC accreditation can offer peace of mind, it’s still important to check your system for the following common installation issues, to help avoid bigger issues in the future.

So, what should you be looking out for?

AC and DC cables in close proximity

One of the fundamental rules for solar PV installations is maintaining separation between AC and DC cables. These cables should never come into contact or be in close proximity to each other, as outlined in Australian standards.

The violation of this rule can lead to potential fires and other operational risks – they must be properly routed and secured to prevent any contact.

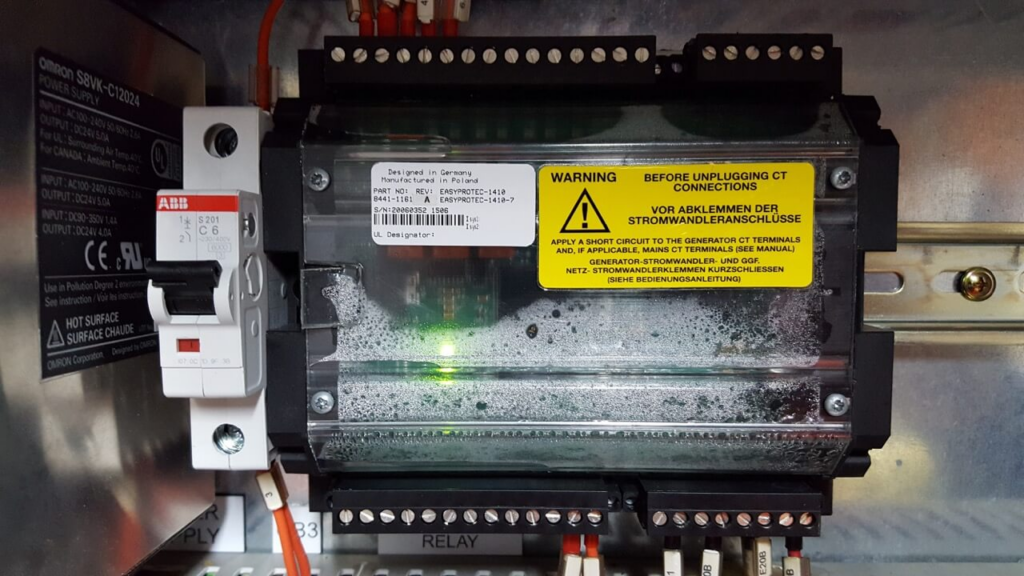

Poor sealing and water ingress

Proper sealing of switchboards is crucial to prevent water ingress and damage to electrical components. If water finds its way into the switchboard, it can lead to short circuits, corrosion, and operational failures – like the system shown in the photo. All entry points must be effectively sealed to prevent moisture infiltrating the system.

Non-compliant minimum cooling gap for inverters

Inverters are required to convert DC electricity generated by the solar panels into usable AC power. Australian standards require a minimum cooling gap between inverters, reducing the risk of overheating or compromised efficiency.

The inverters found during a site audit as shown above are not adequately spaced, impacting the system’s warranty and rendering it non-compliant with Australian standards.

Insecure rail fixings

Solar panels need to withstand wind loads and other environmental forces, which is why it’s so important to ensure the rails are securely fixed. If not, this can lead to instability, increasing the risk of panel displacement and potential damage to the roof and system as a whole.

No separating material between clamps and roof

Another common issue found during solar audits with the potential for damage, is not using a separating material between the clamps and the roof. This can lead to the corrosion and deterioration of roof sheets, affecting the structural integrity of the roof and compromising the system’s efficiency.

Violation of cable contact regulations

Cables in contact with metal roofs are not permitted under the AS/NZS 5033 standard. This is an electrical hazard, posing a risk to the system and the occupants of the building.

Use of non-compliant materials

The materials used for cable management and entry points must be carefully considered, as non-compliant materials can have a detrimental effect on the system’s performance.

Nylon ties, as found at this solar audit, are prone to deterioration over time and can result in cable failures. Additionally, using non-compliant parts, such as the white gland below, can impact the system’s warranty and overall functionality. The correct method in this case would be to use stainless steel ties for securing the cables.

Ensuring safety and compliance with solar audits

Flow Power’s team has been providing solar audits since 2016, making systems safe with a rigorous and uncompromising approach to compliance.

Conducted by qualified electricians and solar specialists, audits are the best way to address common installation issues and ensure your system is up to standard.

When something as seemingly harmless as a loose cable could invalidate your warranty – why take the risk?

Choosing the right installer

Just like solar PV components, there’s a varying level of skill and quality among installers. So, how can you ensure you’re choosing the right team for the job?

Under the current Clean Energy Council guidelines, an installer can sign off on two installs per day, and they only need to be at set up, mid job and testing and commissioning. They can even apply for an exemption to sign off on more per day.

They might get the job done for less – but this leaves a lot of room for error during installation.

What makes us different?

Flow Power’s solar team requires the accredited installer to be onsite throughout the installation, delivering your project, from start to finish.

This is an investment in the quality of your system, giving you peace of mind that it will be safe, efficient, and compliant. Explore all our solar case studies.

Our award-winning team has been delivering quality systems since 2009, using industry-leading components, innovative design, and experienced, accredited installers.

Whether you need an audit of your existing system, or installation of your new solar panels, get in contact with our expert team today.